Hks Evc 4 Boost Controller Manual

Instruction Manual Installation. EVC Boost Controller- Automotive Turbocharged. Star wars comic books. The HKS EVC enables the adjustment of the boost setting from inside.

Hks Evc S Manual

During the late ’80s, the HKS M300 twin-turbo Celica was the first Japanese car to break the 300km/h record with a top speed of 301.25 km/h at the oval course in Yatabe, Japan (5.5km oval with huge bank on the corner). At the time, Yatabe was known as the longest and only track for measuring top speed.

While attempting to set a new domestic top speed record, HKS engineers found boost stability under high engine load and high speed a major concern. In order to maintain stable boost, HKS began the development of the world’s first electric boost controller. The EVC continued to evolve throughout the years with the release of the newest and most current sixth-generation model by incorporating additional features into the all-new EVC 6. The latest HKS EVC offers improved boost stability for maintaining pressure at high rpm providing increased top end power and retaining the same mapping feature as the previous generation, allowing boost pressure to be precisely tuned for throttle +/- rpm (or vehicle speed). It still allows users to set a desired target boost setting, a selectable kPa or psi unit of measure, and a unique warning feature, where if over-boosting occurs, boost pressure can be programmed to drop to a user preset level.

In addition, the EVC features additional improvement from the previous models including, LCD color monitor, smaller physical stepper motor, faster processor, and third boost setting. The new version can also be oriented in two different ways: buttons on the right (traditional) or buttons on the left, and data-logging capability to monitor parameters such as boost, engine speed (or speed), and throttle opening for additional data. HKS engineers have managed to simplify the use of the EVC further, by designing it with a four-button user interface, which makes setup and tuning intuitive and simple. These buttons do not have a directional control sequence that needs to be toggled up or down; rather they simply work by a simple one-touch push. This design was implemented specifically to accommodate drivers to input settings as quickly and efficiently as possible. How simple are the functions, you ask? Pressing the number one (top button) activates the “main” scramble boost while the screen is displayed.

Boost can be switched between modes by pressing the second button from the top. The third button controls the screen brightness, while pressing the button on the bottom allows the end user to toggle though the menu. Yes, it’s that easy. Visually stunning, the design of the new EVC features a sleek black case with a clear acrylic faceplate often overshadowed by the debut of its new color screen display. The EVC has changed significantly with its adaptation of a TFT color LCD.

The 320x240 LCD panel allows additional information to be displayed under any lighting condition. The full-color display makes the new EVC easier to read and navigate through the menu’s color display warnings and scramble boost settings. Compared to the older EVC models, including the EVC 5 model, the monochrome LCD display in black and white was only capable of displaying certain shapes, numbers, or characters. The EVC 6 possesses a completely different layout and number of items, as the new screen allows you to display multiple pages in easier-to-read graphs. The first thing you’d notice different on the new EVC is the stepper motor system, which is more compact, about two thirds in size than its predecessor, and comes in a more durable housing. The new solenoid has also undergone major changes, including a new valve system that significantly improves the performance of the controller. HKS’ traditional stepper motor is controlled by the flow of air into and out of a hole in the solenoid orifice by a shaft driven by a stepping motor.

HKS has maintained the stepper motor design since the first-generation EVC, continually making improvements throughout generation models. HKS engineers claim that the newest EVC speeds up the reaction rate and efficiency of the stepper motor by three times compared to previous models.

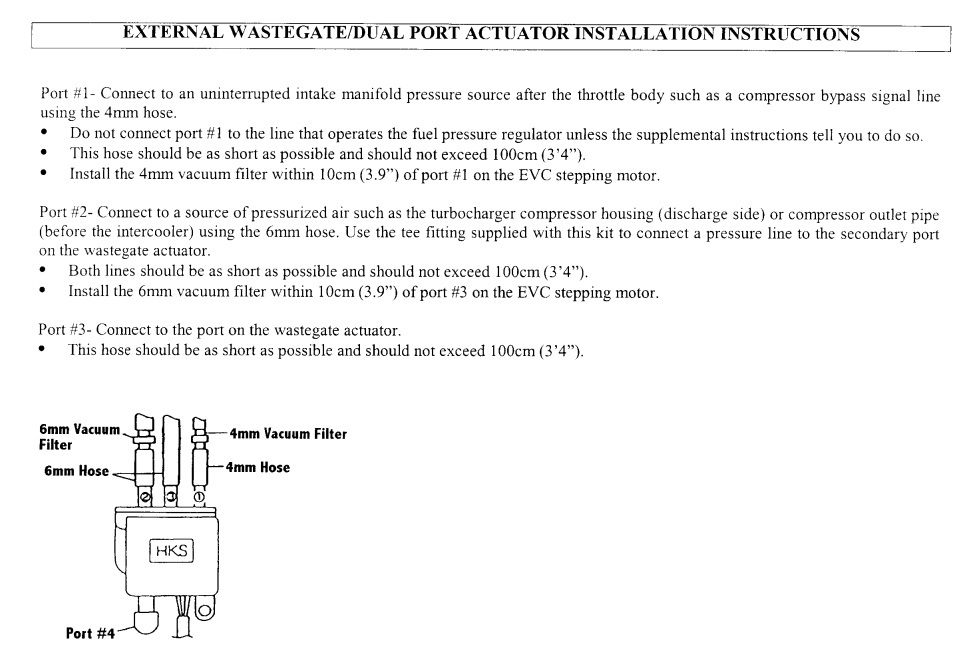

This manual assumes that you have the knowledge in the operation of tools and equipment that are necessary to safely perform service operations on your vehicle. This manual also assumes that you are familiar with typical automotive systems and basic service and repair procedures. Always have access to a factory repair manual as some of the procedures and specifications required for the proper installation of this product may be referenced to the factory repair manual. To avoid the risk of personal injury, follow the lifting, supporting, and safety precautions contained in the factory repair manual. Inspect the filters every 3000 miles. They must be clean for the EVC to function correctly.

If the filter is contaminated or dirty, replace with a new (4mm) 4599-RA017 or (6mm) 4599-RA016. Do not attempt to clean the vacuum filter. If the filters frequently need replacement, relocating the pressure source may solve the problem. Connect the red wire (2-pin harness) f rom the EVC to a 12-volt ignition source.

Utilizing a voltmeter, find a wire that receives at least 12 volts with the key in the “IGNITION” position. Connect the black wire (2-pin h arness) from the EVC to a ch assis ground. Make su re there is no paint or ru st on the ground surface. If there is, sand the surface until bare metal is exposed.